I have started to write these essays to get myself back in the practice of writing. I often talk about hand sewing being a practice, writing is also a practice. In 2017 I finished my thesis which interrogated the context of a cap that Martha Washington wore in the Washington family portrait. While that thesis is available for you to read I have more I want to write and am working on turning sections of it into articles. I also want to write a book on hand-sewing. I see this as “early access” to these drafts. If you have suggestions about topics I am writing on or if there is research you are interested to know about I am open to feedback and suggestions.

Charlot’s Cap

The fashion industry in the United States was founded on the use of enslaved workers, hand stitching clothing together and providing the labor necessary to keep shops running. Many of the women who sewed in bondage have been forgotten. This essay seeks to re-stitch a woman named Charlot back into the history of the American fashion industry using my knowledge of sewing and my study of eighteenth-century caps and shirts worn in the Atlantic World.

Like many histories in the US the story of hand sewing has been white washed. Images of Betsy Ross and white women sitting by the fire side spinning has propagated a problematic mythology that industrious white housewives made all of their families clothing. Beyond being untrue, this narrative has erased the labor of skilled free women of color and a large group of enslaved women who sewed in bondage for themselves and their enslavers within the Atlantic world during the eighteenth century.

Edward Savage (American, 1761-1817), The Washington Family, 1789-1796, Andrew W. Mellon Collection, Open Access Image Courtesy National Gallery of Art, Washington, D.C. (1940.1.2).

Collections of historical garments survive from the eighteenth-century Atlantic World. Because of survival bias these collections skew towards garments worn by wealthy, white colonizers. Unlike silver, a garment was not labeled or marked by its maker during the eighteenth century. While many of these garments were worn by white colonizer’s the stories of dyers, weavers, laundresses, and enslaved seamstresses are also held in the seams.

As part of my Master’s thesis I contextualized the cap worn by Martha Washington in the portrait “The Washington Family.” One of my questions was — who made it? Because there were 317 enslaved people at Mount Vernon in 1799 I thought it likely that an enslaved woman had a hand in the sewing.

As I read through letters between Martha Washington and Fanny Bassett Washington, Charlot and a woman named Caroline jumped off the page. In these passages Charlot’s skill was being described. Her enslaver writes on June 5, 1791:

“I sent by Hercules some rufles for my little Boys bosom [ruffles] which I beg you will make Charlot hem…”

Later in August 29, 1791 she complains:

“I wish you’d had them whipped [i.e. whip-stitched and gathered]--it was but little more trouble for Charlot, they cannot be sewed on the wristbands till they are whipped--”

Shirt with bosom ruffles. Metropolitan Museums of Art, Shirt, 1790, 2009.300.62.

Cap with caul, band and border labeled.

Through my own ‘hand sewn literacy’ I understood what was being described. Charlot could hem fine textiles and was being forced to whip ruffles like the ones you see in the shirt above. This technique is also used in cap making to gather and attach the caul and the border (see left image). Remarkably, a cap that looks very similar to the cap in “The Washington Family” portrait is held in Mount Vernon’s clothing collection. I had the opportunity to study this cap.

Caul attachment to headpiece detail. Cap, Courtesy of the Mount Vernon Ladies’ Association (W-608). Photograph by Sarah Woodyard©. (For more images of this cap go to my thesis here pp. 127, 131, 132 )

(Detail) Edward Savage (American, 1761-1817), The Washington Family, 1789-1796,

Andrew W. Mellon Collection, Open Access Image Courtesy National Gallery of Art, Washington, D.C. (1940.1.2).

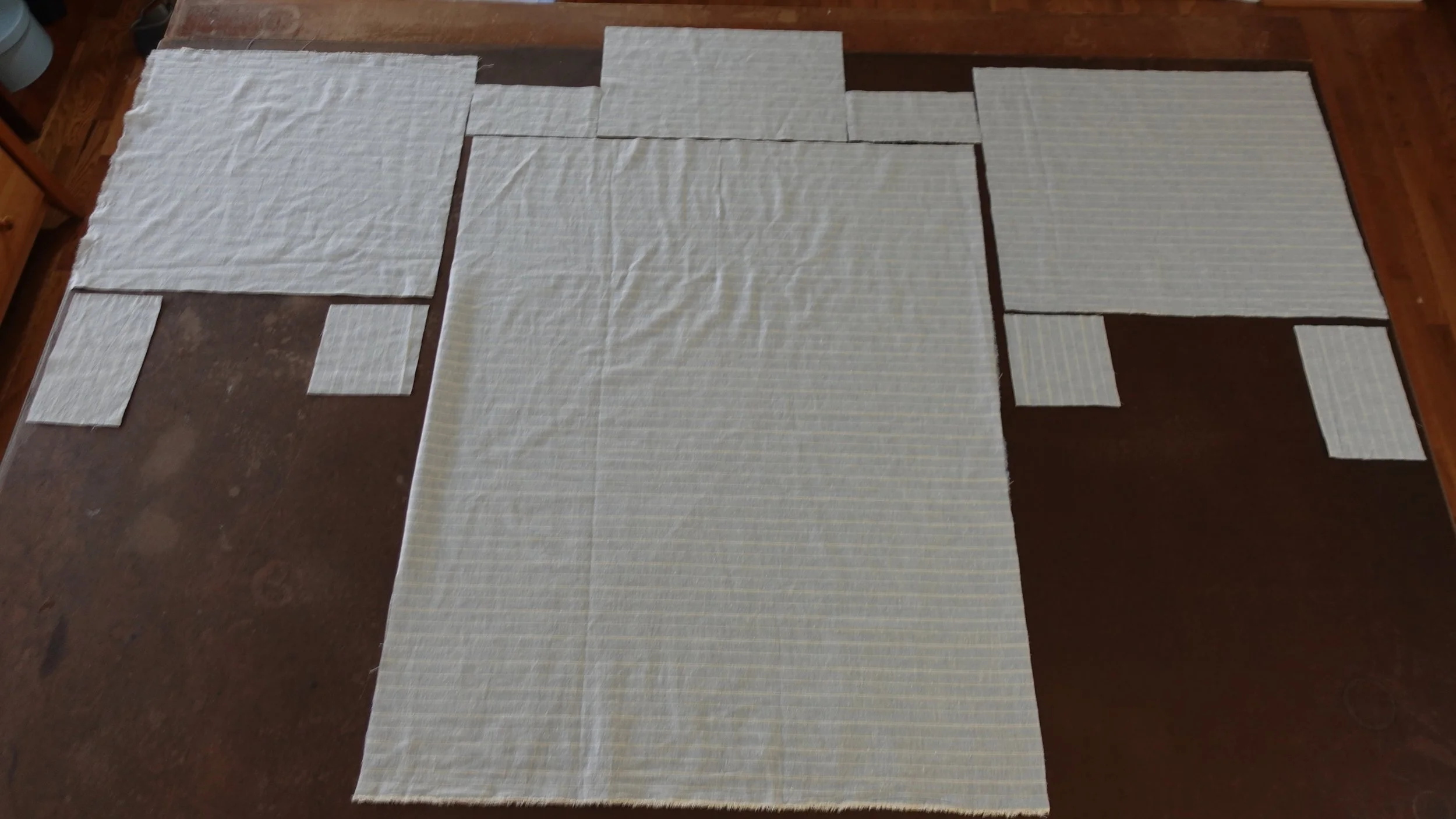

Above you see a detailed view of the crown of the extant cap. The ribbon in the image on the right is separate and would cover this section. Notice how the fabric is gathered. This is created by cutting a larger piece of fabric and using a whip-gathering technique to control the excess material down to a smaller section- in this instance the band. This is the same technique described to whip the bosom ruffles.

Detail of whip gathering.

Through my own sewing practice I was able to see Charlot within the context of her enslavement. Charlot could very well be the woman behind-the-seams of this cap that was used by her enslaver Martha Washington to craft an iconic American image eclipsing Charlot and other women like Caroline and Oney Judge. But now we can see Charlot— her skill and her humanity. Forcing us to hold the beauty of her sewing within the brutal context of her bondage.

I often wonder what skills and life she would have had outside of slavery. Would she have taken the skill and made it paid work like Elizabeth Keckley; a formerly enslaved seamstress who bought her freedom and became Mary Todd Lincoln’s dressmaker? Would she have turned her back on it to escape her bondage physically and spiritually?

Slavery still exists in the United States (and Global) fashion industry, let us honor Charlot and not perpetuate this system. Seek out more stories of women like Charlot in extant eighteenth-century hand-sewn clothing. This is why context with sewing matters— there is always a person behind the seams.

Further Reading:

Black Designers in American Fashion

Database of Mount Vernon's Enslaved Community

Consumed: The Need for Collective Change: Colonialism, Climate Change, and Consumerism